Throughout the year, we caught up with colleagues around the world to hear more about their passion for aviation. Find out which aircraft parts are their favorites, and why.

Our Passion for Aviation

Throughout our 100+ year history, our enthusiasm for aviation has always united us. Beyond our passion for our industry, our global teams also share a deep understanding of the total aircraft - from nose to tail. This year we shared some of their stories on our social media channels. Read on to find out about their favorite aircraft parts, and what makes them so special.

For Business Development Manager Vincenzo Falcone, the development of the engine is incredibly important for the future of the aviation industry. "I consider the engines to be the heart of the aircraft. They provide the thrust to fly and, via the engine accessories, are fundamental for the operation of the aircraft in all stages of the passengers’ journey. Aircraft engines have evolved over the years and play an important role in making aviation more sustainable. Many companies are investing in R&D to create alternative eco-friendly propulsion technologies, with the vision to have zero-emission commercial flights in the future. I look forward to seeing these developments in our industry."

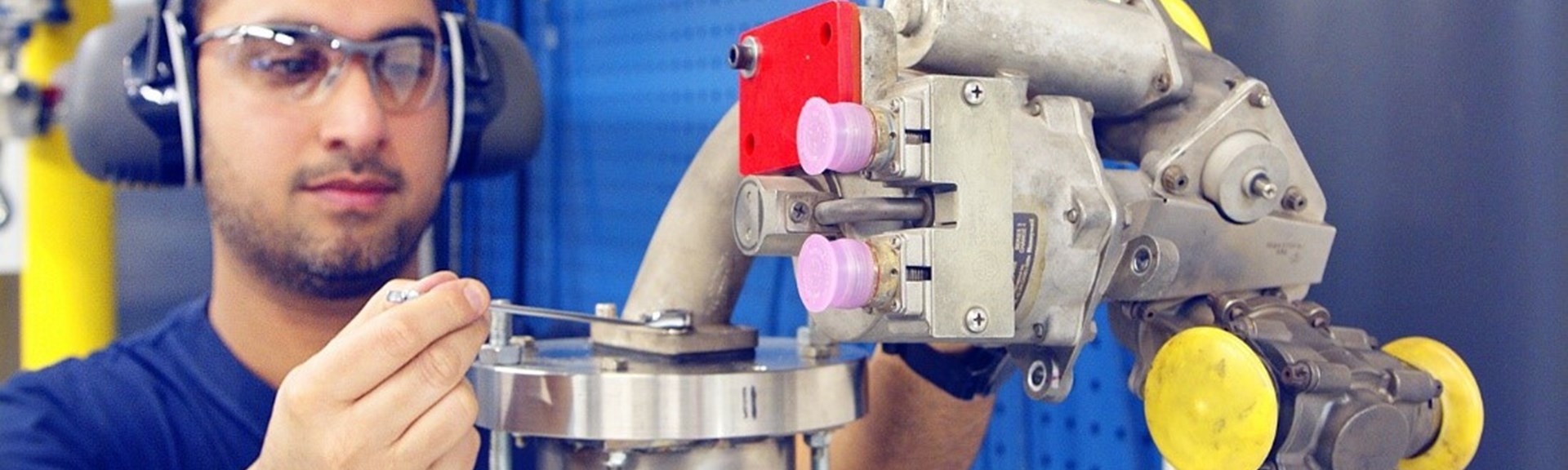

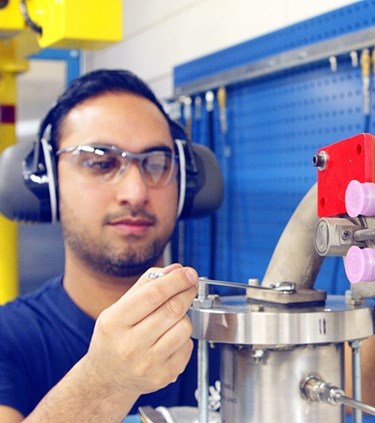

For Adnan Hanif, who is part of our Certifying Staff team at Schiphol, the Netherlands, the High Pressure Turbine Clearance Control Valve is a component he has serviced many time before. “The HPTCC Valve is a critical part in an engine. It transfers air from the compressor to cool the turbine. This advanced technology increases fuel efficiency by controlling the thermal expansion of the turbine blades to optimize tip clearance, and also prevents rubbing on the casing. Knowing the important effect that it has on an engine, I am proud to be part of an organization that services these parts.”

Daan Eelman is a Customer Support Representative based in Hoofddorp, the Netherlands. His favorite aircraft part has been clear from as early as he can remember. "Ever since I first stepped onto an airplane as a child, I have always been fascinated with the technology behind the flight deck. My curiosity lead me to research these instruments more, and I even studied this in detail while at university. I love how everything comes together in the cockpit, with information integrated and displayed in one place so pilots can make decisions and handle different situations as safely as possible. The flight deck has evolved over the years, and to me, it’s truly iconic."

"The horizontal tailplane or stabilizer, from an aircraft design point of view, is a fundamental element that ensures longitudinal stability during flight," said Charlotte Zohlandt, our Manager for Customer Programs in the same team as Daan. "Changing the size and location of this surface can completely change the aerodynamic stability and efficiency. For example, in a canard configuration the stabilizer is located at the nose instead of the tail of the aircraft and generates a force that contributes to the lift. In an even more innovative configuration such as the prandtl plane, the stabilizing surface would actually be designed as one with the wing surface, with the additional benefit of minimizing the lift induced drag.”

Moving over to our colleagues in LaGrange, Georgia, Charlotte Coffey knows the Air Cycle Machines all too well in her role as Program Manager. For her, it's all about making sure that our customers receive the best services to keep their components in excellent condition. "It’s always during the hot summer months that we see many Air Cycle Machines come through our shop," said Charlotte Coffey, Program Manager in LaGrange. "Running at 37,000 RPM and with a complex build standard, this part requires serious expertise. My colleagues here in the U.S. have 100+ years of combined experience in servicing these parts – and it’s always a great feeling to tell our customers that their ACM is back to full reliability."

Follow us on LinkedIn and Twitter to hear more stories from our colleagues at Fokker Services.