Discover the technology used day in, day out, at our component maintenance, repair and overhaul shop in the U.S.

3 minute read.

Discover the technology used day in, day out, at our component maintenance, repair and overhaul shop in the U.S.

3 minute read.

As every component MRO shop knows, reliability is key. Behind the scenes we continuously look to implement improvements in technologies, and new computer systems, to ensure quality and accuracy. With multiple dedicated test cells on-site at our facility in LaGrange, Georgia, discover more about the benefits and services some of these machines have to offer.

By simulating aircraft conditions, the Eddy Current Dynamometer Test Stand sensors measure the vibration, air pressure, torque, and RPM to ensure that the engine air starter is in top condition. Using this test stand, we digitized and simplified the recording process for our technicians by using industry-leading software. By reviewing the highly accurate data results, our technicians make a detailed diagnostic assessment on many different types of air turbine starters.

Taking up a whole cell due to its large set up, the Air Driven Pump (ADP) test stand is one of our most recognizable pieces of equipment. It is another example of how we leverage technology to aid in testing and ensure accurate results. With computer-driven data acquisition built into the ADP test stand, the software and hardware work together to provide accurate testing of the pneumatic and hydraulic systems of the ADP.

Our technicians make detailed diagnostic assessments.

Over the last few years, we have made significant improvements to our Air Cycle Machine (ACM) test cell. The upgrades, which included an overhaul of the test cell software and hardware, were developed with the technicians’ direct feedback so their expertise could be implemented into the test cell. This unique test stand is not only accurate, but also simplifies the testing operation, reducing human errors in the testing process. Once installed into the test cell, an ACM can be operationally tested from the computer console outside of the cell, all while providing the technician with specific and accurate data simultaneously.

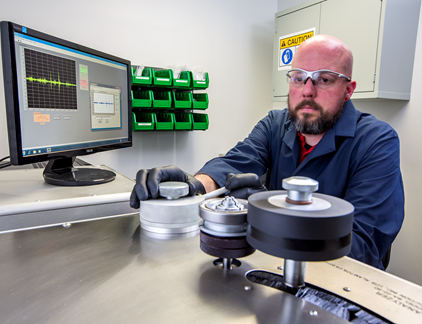

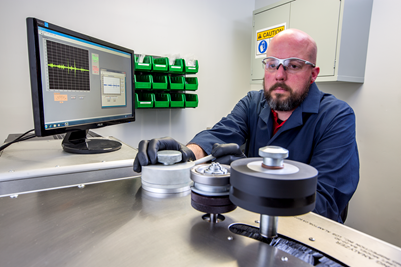

Another specialized piece of equipment in our shop is the Ball Bearing Analyzer (BBA), which accurately measures the vibrations in the ball bearing to determine its condition. BBAs can often be found at bearing manufacturers and resellers, but not typically at a repair station like ours. With bearing inspections completed in-house at LaGrange, we can quickly determine if a costly bearing is serviceable, repairable or non-serviceable. This saves time and costs, while fulfilling our customers’ needs for dependable services and quick turnaround times.

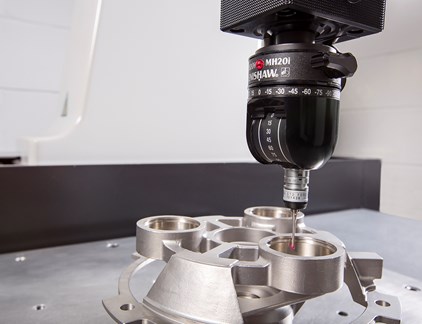

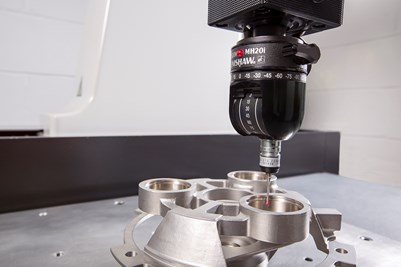

The Coordinate Measuring Machine (CMM) is a long-standing piece of equipment that sets us apart from other shops. It aids our engineering team in the development of unique solutions for minor repairs that specifically meet our customers’ needs. Using the highly accurate dimensions provided by the CMM, our team reverse engineer OEM components on-site, developing and modeling drawings to have new parts manufactured. By developing and substantiating our own repairs and fabricated parts, we can control stock levels and do not need to wait for component deliveries from the OEM or wider market. In the end, we can pass on these cost and time saving benefits to our customers.

Alongside these specialized and customized test stands, our LaGrange shop also features a data-driven Hydraulic Test Cell, electric Fans cell, and more. To find out more about the services and capabilities, contact us via the link below.